OUR OLIVE TREE

We pay special attention to caring for our olive grove (soil and olive trees) to maintain its normal growth and good production.

The climate and location provide it with oxygen, sunlight, temperature (cold weather), water, and natural nutrients, such as nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, iron, manganese, copper, zinc, molybdenum, boron, and chlorine, necessary for the correct development of the olive tree. Additionally, in certain areas, we assist with scheduled irrigation and/or fertilization (both through root and foliar application).

The monitoring of the entire cultivation and care process of our olive grove, including irrigation, nutrition, and pruning, among others, is carried out by specialized and experienced technical personnel, such as agricultural engineers, who record each step in our Field Notebook. This control allows for better and greater traceability.

We analyze and observe the soil profile of each zone in the olive grove throughout the year: its physical appearance, texture, presence of stones, structure, porosity, water storage capacity, density, consistency, color, temperature, material, reaction, salinity, quantity of microorganisms… because it is very useful for improving decision-making regarding the same olive grove and the campaign in general.

Our olive trees are of the Olea europaea variety

How do we work it?

Our soil system involves tillage under the olive trees and no-tillage in the rows. We consider how tillage influences olive production and the environment, based on aspects such as water absorption and conservation, degradation, and the risk of erosion, the amount of organic matter and plant/animal residues, and susceptibility to diseases.

We have an intensive area in the olive grove.

- The olive trees, with a single trunk, are isolated and planted in frames of 7×5 meters with a density of 150 trees per hectare, with wide rows or aisles of 7 meters.

- The lifespan of the plants is over 40 years. It is equipped with drip irrigation, facilitating mechanized harvesting with buggies; facilitating control, nutrition, and pruning; avoiding injuring the olive trees during the harvesting season.

Another small part of our olive grove is arranged in a super-intensive system, which is yielding very good results with our Arbequina variety.

- It consists of rows of very young olive trees arranged in hedges, with densities ranging from 1000-2000 trees per hectare.

- The spacing between olive trees is between 1.25-1.5m, with 4m-wide rows.

- The lifespan of the plants is about 15 years, so after that period, we renew the plantations.

- It is equipped with automatic irrigation and is harvested mechanically with harvesters.

PRUNE

We prune the branches of the olive trees, always in a controlled and environmentally respectful manner, to thin or reduce them, thus balancing growth and fruiting, shortening the unproductive period, extending the productive one, and revitalizing the olive tree (we avoid prematurely aging it).

We always reuse pruning residues as part of natural fertilizer.

We prune the lower branches to obtain a tree shape with one trunk and three to five main branches. We take care to keep the center open so that water and light can penetrate without difficulty (that’s why it doesn’t have a spherical shape, which could be visually more appealing, like a decoration).

PROCESS OF ELABORATION OF OUR AOVE

El proceso de elaboración de nuestro aceite de oliva virgen extra se divide en varios pasos:

vacios

1 - COLLECTION

The campaign begins with the olive harvest: we usually start it in late October and it lasts until mid-November (about 20-25 days), and we do it in batches based on their gradual and optimal ripening, and according to the area of the olive grove and its soil and climate conditions.

The olives are harvested just before they turn from green to purple (veraison). It is called “early harvesting” and does not mean that it is harvested prematurely, but rather in the early phase of its ripening. We only collect fresh and healthy flying olives (never from the ground) and using modern and fast harvesting equipment, by specialized personnel.

Depending on the area of the olive grove and the ripening stage of the olives, we combine different harvesting systems, classified according to their complexity and productivity.

Some batches are harvested by hand, directly from the tree (they do not damage the fruit or the tree) and are allowed to fall onto a mesh placed on the ground to then be emptied into trailers (a very slow and costly process). Some batches are harvested using beating with a comb, which are mechanized rods with a comb or fine rake at the end. But the majority of the olives are harvested with buggies or tractors with a vibrating arm that attaches to the branches and trunks of the olive trees to make them vibrate until they fall onto a large collecting umbrella, spread out previously under the perimeter of the olive tree (they are highly maneuverable, quality, effective, and productive) And for the part of the olive grove planted in super-intensive, we use a harvester.

We follow the strict rules, protocols, and guidelines of our field and mill management body, controlling each batch according to the ripeness and health of the olives, and the harvest hours (not in high temperatures and if it does not rain).

We avoid delays in harvesting so that the olives do not lose their health and thus the quality of the oil we extract.

We conduct thorough control of each harvested batch, to monitor traceability.

2 - TRANSPORT AND RECEPTION

Once harvested, the olives are transported quickly and in small quantities to the mill to maintain their freshness.

We must prevent them from fermenting, oxidizing naturally due to stacking in trailers, or due to high temperatures, causing them to lose aromatic, flavor, or nutritional properties, which would result in unpleasant odors reflected in the oil produced (it would be “rancid”).

Therefore, the time elapsed between the olive harvest and its deposit in the mill is crucial: within an hour, we have the olives ready for oil extraction.

The olive, upon harvesting and as time passes, under the sun and potential heat, and through the intrinsic fermentation process, increases a few degrees in temperature. That’s why it’s important to unload them quickly, avoid stacking them for too long, and start the milling process as soon as possible (this also helps prevent the proliferation of any potential bacteria, as they thrive better at higher temperatures).

The harvested olives are deposited in the reception yard. Ours is covered to avoid direct sunlight and better control external temperature changes.

In the control booth, specialized technical personnel verify their quality, uniform ripening, and healthiness once again. We unload the olives into a hopper that, through regulatory food conveyor belts (white, not rubber), passes them through a mechanical blowing system to remove branches and leaves.

The branches and leaves are deposited in separate hoppers for reuse as compost. The clean olives continue along the conveyor belts to the scale, where they are weighed, and the inputs are recorded in batches to control traceability (all at a speed that prevents stacking). From here, they continue along the conveyor belts to the mill.

The time elapsed from olive harvesting to entering the mill does not exceed half an hour.

We believe it’s not necessary to wash the olives. They come directly from the olive tree and are carefully maintained in terms of hygiene and preservation state. Therefore, we don’t see it as necessary (also, we don’t want to add more water to the process, as it would alter the sensory result).

Our annual/seasonal olive processing (milling) capacity is up to 3,500 kg/h / 2,000,000 kg.

3 and 4 - GRINDING AND BEATING

The mill is responsible for crushing the olives. We use a hammer mill, where we regulate the size of the sieve to be used, depending on the batch of olives being processed, and the speed, as we grind at a low speed to avoid increasing the temperature of the olives.

The contents of the mill are transferred to the mixer through a food-grade pipe.

The mixer is a double vertical, cylindrical drum, made of food-grade stainless steel. Inside, it has helical blades that slowly and continuously stir the broken olives from the mill, turning them into a homogeneous paste. The inner drum is surrounded by a jacket (a network of pipes) through which water circulates at a variable temperature to cool the outer drum, keeping the paste inside below 27º C (low temperature).

This paste has no contact with the outside or direct oxygen, to preserve as many volatile compounds as possible and balance the bitter and pungent notes. It’s an anti-oxidative mixing process.

During the mixing period, the oil/water emulsion is broken and oil vacuoles (small oil molecules that become droplets) are generated. Occasionally, a small amount of them may appear on the surface of the paste, called “oily must” or “oil flower”, indicating that it is time to move on to the horizontal centrifuge to extract all the oil.

5 - COLD EXTRACTION

We mechanically extract the oil using a horizontal centrifuge, also called a decanter. Inside, there is a horizontal steel cylinder with a helical screw responsible for introducing the paste, centrifuging it, and separating:

On one side: the oil. On the other: the vegetation water (typical of the olive) and the remains of dry mass (skin, flesh, and bone). It is the pomace: husk + pulp.

It is, therefore, a two-phase, biphasic system. Horizontal Centrifuge (biphasic): by centrifugal force in the paste, concentric rings are created, taking advantage of the high rotation speed and the different specific weight of the parts to be separated, i.e., by their densities.

Inside, without oxygen, the decanter accumulates the pomace in the tapered part of the cylinder, the outer part of the rings, and through a valve it exits to the exterior. And, with the same centrifugal force, it drags the oil from the inner ring to the opposite end, which through the diaphragm (hole) passes through another tube to a tank (anti-oxidative extraction process).

We control the degree of diaphragm opening to avoid mass mixing at the ring boundaries. To obtain oil free of natural residues, we do not allow pomace to pass through the diaphragm; and we allow a little oil to pass through the pomace tube.

We treat the pomace again with a depitter.

Through a mechanized system by centrifugal force, the stone (possibly some skin) is separated from the rest of the olive skin and flesh. It is blown and left to dry, manually moving it with shovels occasionally so that natural fermentation does not increase the interior temperature and cause a fire. Once dry, a large part of the stone is used in the mill as fuel for the boiler and a smaller part is sold to third parties. The rest of the pomace is sold immediately to those companies that centrifuge it again to extract all the possible oil (to produce crude pomace oil) and whatever may remain of the stone (to produce fuel).

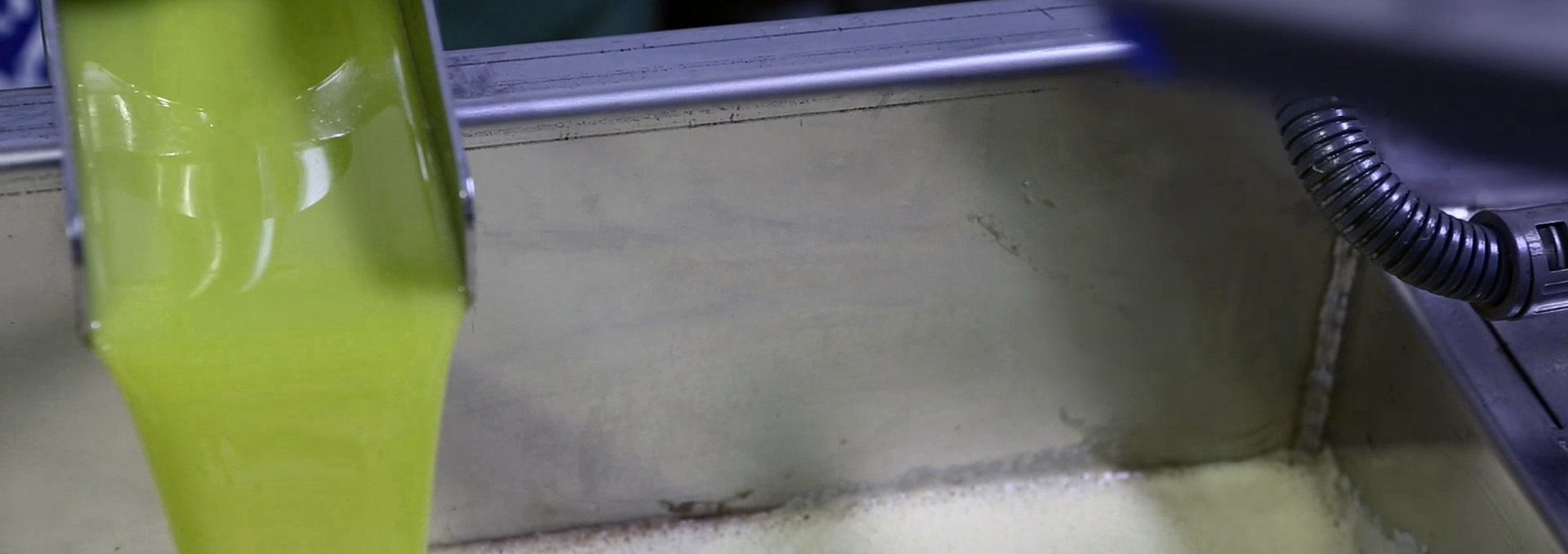

About the extracted oil, it is worth mentioning that the achieved aroma and color are pleasantly surprising. Its color is intense green and its texture is turbid. It overflows with countless magnificent, powerful herbaceous and fruity aromas, with even spicy notes, which impregnate the mill and fill it with freshness.

6 - FILTERING

The freshly produced oil is not considered ready for bottling. We could, because it has an exquisite aroma and flavor, but we prefer to clean it and remove possible tiny impurities that could spoil the oil over time, as it evolves once stored.

As a safety measure, to remove any possible small solid particles that may remain and then ferment, we decant the oil into specially prepared stainless steel tanks for a maximum of 12 hours, depending on the batch. Thus, the oil settles and we clean it with purges every 1.5 hours. To better eliminate these small particles, with maximum care and attention to avoid losing volatiles and maintain the balance of bitterness and spiciness, we continue with the removal of the ‘fines’ using the vertical centrifuge. We remove the tiny particles of skin and bone, as well as any remaining vegetation water and washing residue, so that in no way can they alter the future taste and olfactory sensations of the produced oil.

And, in case there are micro-particles left, we subsequently filter the oil with cellulose plates. It represents a gentle devastation to remove moisture and eliminate impurities in a non-aggressive manner.

7 - STORAGE AND ANALYSIS

In order to preserve over time all the freshness, aromas, flavor, and natural micronutrients that the oil possesses, we store it in batches:

In food-grade stainless steel tanks inertized with food-grade nitrogen, introduced by punctual bazuqueo from below, to prevent the loss of volatiles and leave no room for oxygen. In a cellar protected from natural light and at a constant temperature of 18ºC, to prevent changes in the volume of oil due to temperature changes and allow the entry of oxygen or the exit of nitrogen.

In the cellar, we control the level of:

CO2 and air renewal, through the use of fans. Humidity: very low (30-40%).

The tanks are bled periodically to remove any possible residues or fines that may settle at the bottom. Our cellar consists of tanks of 27,000 and 58,000 kg of oil each, ordered by number.

8 - PACKAGING